Galvanized steel plate

Classification and Use

According to production and processing methods, it can be divided into the following categories:

1. Alloyed galvanized steel plate. This kind of steel plate is also made by hot-dip method, but it is heated to the alloy coating of zinc and iron is formed at about 50O ℃. This galvanized sheet has good coating adhesion sex and weldability.

2. Hot-dip galvanized steel plate. Immerse the steel plate into the molten Duo groove to make it adhere to a layer of Duo steel plate.

At present, it is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in the molten zinc plating bath to make galvanized steel plate.

3. Electrogalvanized steel plate. The galvanized steel sheet manufactured by electroplating method has good workability. However, the coating is thinner and the corrosion resistance is not as good as that of hot-dip galvanized sheet; ④ Alloy and composite galvanized steel plate. It is a steel plate made of zinc and other metals such as lead and zinc. This kind of steel plate not only has excellent anti-rust performance, but also has good coating performance.

4. Single-sided galvanized steel plate and double-sided differential galvanized steel plate Single-sided galvanized steel plate, that is, products that are galvanized on one side only. It has better adaptability than double-sided galvanized sheet in coal welding, coating, anti-rust treatment, processing, etc. In order to overcome the disadvantage of not coating zinc on one side, there is another kind of galvanized sheet coated with a thin layer of zinc on the other side, that is, double and differential zinc sheet.

5. Alloy and composite galvanized steel plate. It is a steel plate made of zinc and other metals such as aluminum, lead, zinc, etc. This kind of steel plate not only has excellent anti-rust performance, but also has good coating performance.

In addition to the above five types, there are also color galvanized steel plate, printing coated galvanized steel plate, PVC laminated galvanized steel plate, etc. However, the most commonly used is still hot-dip galvanized sheet.

Appearance

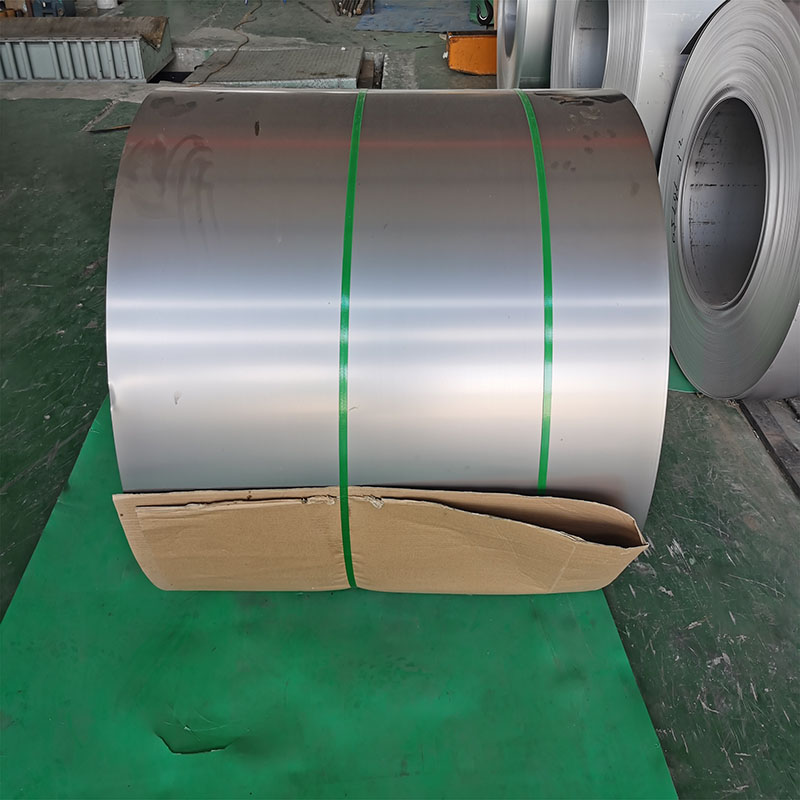

1. Packaging

It can be divided into two types: galvanized sheet cut into fixed length and galvanized sheet with coil. General iron sheet packaging is lined with moisture-proof paper, and the outside is tied with iron waist, which is fastened firmly to prevent the inner galvanized sheet from rubbing against each other.

2. Specification and size

Relevant product dimensions (such as the following and) list the recommended dimensions, thickness, length and width of galvanized sheet and their allowable defects. In addition, the width and length of the board and the width of the roll can also be determined according to the user's request.

3. Surface

General situation: because of the different treatment methods in the coating process, the general situation of galvanized sheet is also different, such as the general situation of ordinary zinc flake, fine zinc flake, flat zinc flake, zinc-free flake and phosphating treatment. The galvanized sheet and galvanized coil cut into a fixed length shall not have any defects that affect the use (as described below), but the coil shall be allowed to have welding parts and other non-deformed parts.

4. Galvanizing quantity

Scale value of galvanizing quantity: galvanizing quantity is a widely adopted and useful method to indicate the thickness of zinc coating on galvanized sheet. There are two types of zinc plating: the same amount of zinc plating on both sides (i.e. equal thickness zinc plating) and the different amount of zinc plating on both sides (i.e. differential thickness zinc plating). The unit of galvanizing quantity is g/m.

5. Machine function

(1) Tensile test: generally speaking, as long as the galvanized sheet for layout, drawing and deep drawing has tensile function requirements.

(2) Bending experiment: It is an important name to weigh the technological function of thin plate. However, the requirements of different countries for various types of galvanized sheet are actually different. Generally, after the galvanized sheet is bent 180 °, the zinc layer shall not leave the outside profile, and the sheet base shall not be cracked or broken.

Features of galvanized steel plate: galvanizing can effectively prevent steel corrosion and prolong service life. Galvanized steel sheet (thickness 0.4~1.2mm) is also called galvanized iron sheet, commonly known as white iron sheet. Galvanized steel sheet is widely used in construction, vehicles, household appliances, daily necessities and other industries.

Size: according to customer requirements, the length and width can be flattened or customized.

Surface state: Due to the different treatment methods in the coating process, the surface state of the galvanized sheet is also different, such as ordinary zinc flake, fine zinc flake, flat zinc flake, non-zinc flake and phosphating surface. The German standard also specifies the surface grade.

The galvanized sheet shall have a good appearance and shall not have defects harmful to the use of the product, such as no plating, holes, cracks, scum, over plating thickness, scratches, chromic acid dirt, white rust, etc. Foreign standards are not very clear about the specific appearance defects. Some specific defects shall be listed in the contract when ordering.

Mechanical Properties

Tensile test:

1. Performance index: Generally speaking, only galvanized sheet for structure, drawing and deep drawing has tensile property requirements. The galvanized sheet for structure shall have yield point, tensile strength and elongation; Only elongation is required for stretching. See relevant product standards in "8" of this section for specific values.

2. Test method: it is the same as the test method for ordinary steel sheet, see the relevant standards provided in "8" and the test method standards listed in "Ordinary carbon steel sheet".

Bending test:

Bending test is the main item to measure the technological performance of the sheet, but the requirements of various national standards on various galvanized sheets are not consistent. The American standards do not require bending and tensile tests except for structural grade. In Japan, bending tests are required except for structural, architectural and general corrugated plates.

Requirements: generally, after the galvanized sheet is bent 180 °, there shall be no separation of zinc layer on the outer surface, and there shall be no crack and fracture on the plate base.

Features and Performance

Color steel plate coating is a product made of cold rolled steel plate, galvanized steel plate, coated (roll coated) or composite organic film (PVC film, etc.) after chemical treatment on the surface, and then baked and cured. Some people also call this product "roller coated steel plate", "plastic color steel plate". Color plate products are rolled by manufacturers on continuous production lines, so they are also called color coated steel plate rolls. Color steel plate not only has high mechanical strength of iron and steel materials, easy to form the performance, but also good decorative coating materials and corrosion resistance. Color steel plate is a new material in today's world. With the progress of science and technology, the enhancement of environmental awareness, the improvement of people's living standards, color steel plate mobile housing more and more shows a strong vitality and broad market prospects, by the construction, home appliances, mechanical and electrical, transportation, interior decoration, office appliances and other industries of favor.

Product Standard

JIS G3302-94 galvanized steel sheet;

JIS G3312-94 painted galvanized iron sheet;

JIS G3313-90 (96) Electrogalvanized steel sheet and strip; General requirements for hot-dip galvanized steel sheet;

ASTM A526-90 commercial grade hot-dip galvanized steel sheet;

ASTMA 527-90 (75) occluded hot-dip galvanized steel sheet;

ASTMA528-90 deep-drawn hot-dip galvanized steel sheet; Hot dip galvanized steel sheet for roof and wall panel;

ASTMA44-89 Hot dip galvanized steel sheet for ditches;

ASTM A446-93 structural grade hot-dip galvanized steel sheet;

ASTMA59-92 cold rolled galvanized steel sheet;

ASTMA642-90 hot-dip galvanized special deoxidized deep-drawing steel sheet;

Γ OCT7118-78 galvanized steel sheet;

DINEN10142-91 Part 1 Low carbon steel hot-dip galvanized steel strip and steel plate;

DIN1012-92 part 2 hot-dip galvanized steel sheet.

Test Standard

JIS H0401-83 Test method for hot-dip galvanizing;

DIN50952-69 Test method for hot-dip galvanizing.

Target

Galvanized sheet and strip steel products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries. The construction industry is mainly used to manufacture anti-corrosive industrial and civil building roof panels, roof grids, etc; The light industry uses it to manufacture home appliance shells, civil chimneys, kitchen utensils, etc., and the automobile industry mainly uses it to manufacture corrosion-resistant parts of cars, etc; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, frozen processing tools for meat and aquatic products, etc; Commerce is mainly used as storage and transportation of materials, packaging tools, etc.