Preferential hot-dip galvanized strip steel

Production Process

Phase I

The whole coil of strip steel shall be pickled and decontaminated to achieve a bright and clean surface.

Phase II

1. Hot-dip galvanizing: after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank. Then it is sent to the hot dip galvanizing tank for galvanizing.

2. Hot galvanizing: after pickling, it is cleaned in the bath of ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution, and then sent into the galvanizing bath after continuous annealing furnace for galvanizing.

3. Direct galvanizing: after pickling, it is sent into the continuous annealing furnace and then into the galvanizing tank for galvanizing.

Phase III

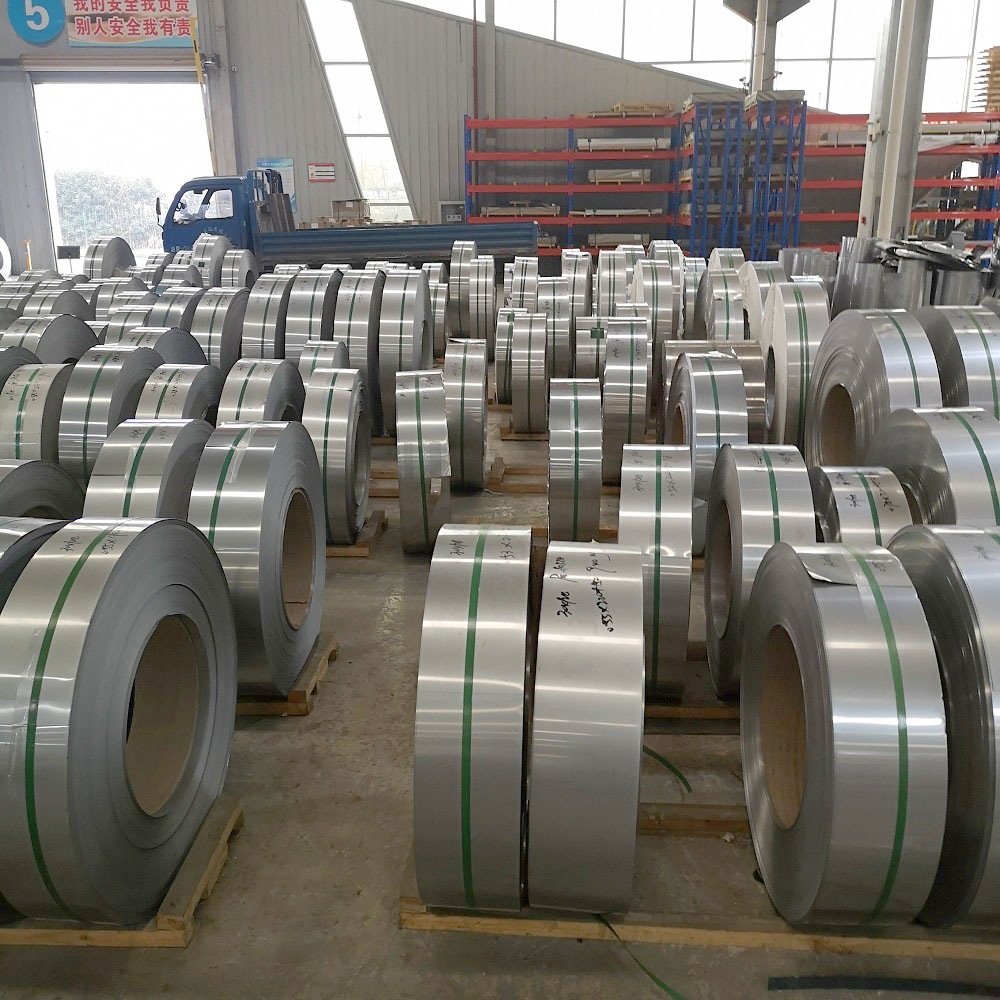

After the strip steel is galvanized, it shall be coiled and put into storage. The galvanized layer can be no less than 50g/m2 according to customer requirements, and any sample shall be no less than 48g/m2.

Galvanized strip steel is generally used to make steel pipes, such as greenhouse pipes, drinking water pipes, heating pipes, and gas transmission pipes; It can also be used in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries.

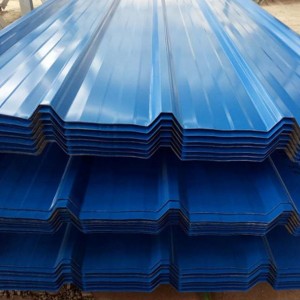

Galvanized steel strip shows that the construction industry is mainly used to manufacture anti-corrosive industrial and civil building roof panels, roof grids, etc; The light industry uses it to manufacture home appliance shells, civil chimneys, kitchen utensils, etc., and the automobile industry mainly uses it to manufacture corrosion-resistant parts of cars, etc; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, frozen processing tools for meat and aquatic products, etc; Commercially, it is mainly used as storage, transportation and packaging equipment of materials; Steel structure sandalwood bar (C, Z shaped steel); Light steel keel, ceiling keel, etc.

Allowable thickness deviation

| Minimum yield strengthMpa | Nominal thicknessmm | Allowable thickness deviation | AccuracyPT.A | High-precision PT.B | Nominal width | ≤1200 | >1200-≤1500 | >1500 | ≤1200 | 1200-≤1500 |

| <280 | s0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 | |||||

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.08 | ±0.04 | ±0.05 | |||||

| >0.60-0.80 | ±0.07 | ±0.08 | ±0.09 | ±0.05 | ±0.06 | |||||

| >0.80-1.00 | ±0.08 | ±0.09 | ±0.10 | ±0.06 | ±0.07 | |||||

| >1.00-1.20 | ±0.09 | ±0.10 | ±0.11 | ±0.07 | ±0.08 | |||||

| >1.20-1.60 | ±0.11 | ±0.12 | ±0.12 | ±0.08 | ±0.09 | |||||

| >1.60-2.00 | ±0.13 | ±0.14 | ±0.14 | ±0.09 | ±0.10 | |||||

| >2.00-2.50 | ±0.15 | ±0.16 | ±0.16 | ±0.11 | ±0.12 | |||||

| >2.50-3.00 | ±0.17 | ±0.18 | ±0.18 | ±0.12 | ±0.13 | |||||

| ≥280 | ≤0.40 | ±0.06 | ±0.07 | ±0.04 | ±0.05 | |||||

| >0.40-0.60 | ±0.07 | ±0.08 | ±0.09 | ±0.05 | ±0.06 | |||||

| >0.60-0.80 | ±0.08 | ±0.09 | ±0.11 | ±0.06 | ±0.06 | |||||

| >0.80-1.00 | ±0.09 | ±0.11 | ±0.12 | ±0.07 | ±0.08 | |||||

| >1.00-1.20 | ±0.11 | ±0.12 | ±0.13 | ±0.08 | ±0.09 | |||||

| >1.20-1.60 | ±0.13 | ±0.14 | ±0.14 | ±0.09 | ±0.11 | |||||

| >1.60-2.00 | ±0.15 | ±0.17 | ±0.17 | ±0.11 | ±0.12 | |||||

| >2.00-2.50 | ±0.18 | ±0.19 | ±0.19 | ±0.13 | ±0.14 | |||||

| >2.50-3.00 | ±0.20 | ±0.21 | ±0.21 | ±0.14 | ±0.15 |

| Nominal width mm | Allowable width deviation (mm) | Normal precision PW.A | Advanced precision PW.B | Minimum value | Maximum | Minimum value | Maximum |

| 2600-1200 | 0 | +5 | 0 | +2 | |||

| 1200-1500 | 0 | +6 | 0 | +2 | |||

| >1500 | 0 | +7 | 0 | +3 | |||

| Allowable deviation of length | |||||||

| Nominal length mm | Allowable deviation of length (mm) | Normal precision PL.A | Advanced precision PL.B | Minimum value | Maximum | Minimum value | Maximum |

| =2000 | 0 | +6 | 0 | +3 | |||

| ≥2000 | 0 | Lengthwise 0.3% | 0 | Lengthwise0.15% | |||

Use of Galvanized Steel Strip

Galvanized strip steel is generally used to make steel pipes, such as greenhouse pipes, drinking water pipes, heating pipes, and gas transmission pipes; It can also be used in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries. The construction industry is mainly used to manufacture anti-corrosive industrial and civil building roof panels, roof grids, etc; The light industry uses it to manufacture home appliance shells, civil chimneys, kitchen utensils, etc., and the automobile industry mainly uses it to manufacture corrosion-resistant parts of cars, etc; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, frozen processing tools for meat and aquatic products, etc; Commercially, it is mainly used as storage, transportation and packaging equipment of materials; Steel structure sandalwood bar (C, Z shaped steel); Light steel keel, ceiling keel, etc.

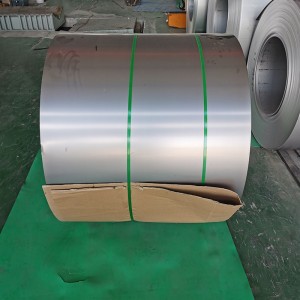

Features of galvanized steel strip: galvanized steel strip is a kind of raw material called (zinc) which is coated on the long and narrow strip steel plate of cold rolling or hot rolling. Hot galvanizing has the advantages of uniform coating, strong adhesion and long service life. The complex physical and chemical reactions between the hot-dip galvanized steel pipe substrate and the molten plating solution form a corrosion-resistant zinc-iron alloy layer with compact structure. The alloy layer is integrated with the pure zin c layer and the strip steel substrate. Therefore, it has strong corrosion resistance. The quality points of galvanized strip steel shall be smooth in appearance, free of zinc nodules and burrs, and silver white; The thickness is controllable, between 5-107 μ Any choice within m; There is no hydrogen embrittlement and temperature hazard, which can ensure that the mechanical properties of the material remain unchanged; It can replace some processes requiring hot galvanizing; Good corrosion resistance, neutral salt spray test up to 240 hours; Etc. Strip steel, also known as steel strip, is within 1300mm in width, and its length is slightly different according to the size of each coil. The strip steel is generally supplied in coils, which has the advantages of high dimensional accuracy, good surface quality, easy processing and material saving.

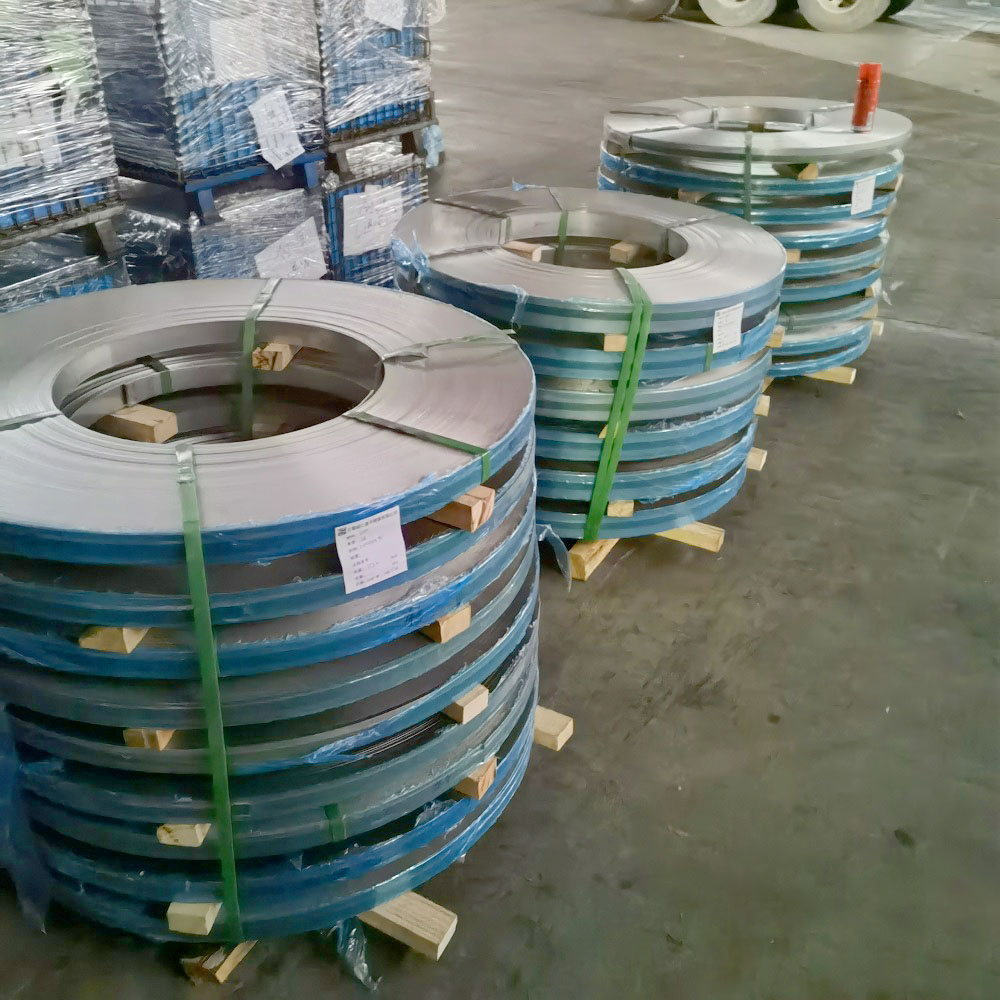

Packing method: bundle, wooden case

Export mode: automobile transportation

Detail Drawing