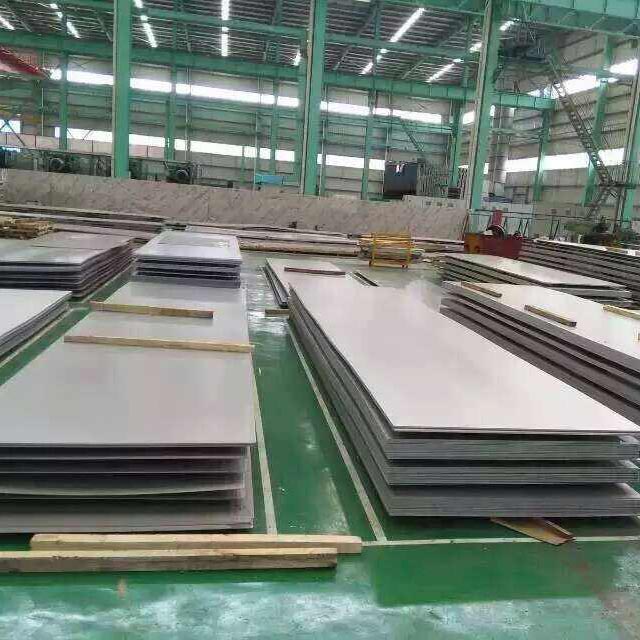

Stainless steel plate

Product Description

According to the production method, there are two kinds of hot rolling and cold rolling, including 0.5-4 mm thick sheet and 4.5-35 mm thick plate.

According to the structural characteristics of steel, it can be divided into five types: austenite, austenitic-ferrite, ferrite, martensite and precipitation hardening.

Use environment: bear the corrosion of oxalic acid, sulfate-ferric sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfate-copper sulfate, phosphoric acid, formic acid, acetic acid and other acids.

Uses: used in chemical, food, medicine, paper, oil, atomic energy and other industries, as well as various parts and components of buildings, kitchenware, tableware, vehicles and household appliances. In order to ensure that the yield strength, tensile strength, elongation, hardness and other mechanical properties of various stainless steel plates meet the requirements, the steel plates must undergo annealing, solution treatment, aging treatment and other heat treatment before delivery.

Quality requirements: stainless steel plate has smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion of acid, alkaline gas, solution and other media. It is an alloy steel that is not easy to rust, but it is not absolutely rust-free. The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and internal structure. The main role is chromium. Chromium has high chemical stability, can form a passivation film on the steel surface, isolate the metal from the outside, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance will decrease.

Chemical Composition

| Unified teaching code | Brand | Chemical composition (mass fraction)/% | ||||||||||||||||||||||||||||||||||

| c | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | Other | ||||||||||||||||||||||||||

| S30408 | 06Cr19Ni10 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 |

8.00~ 10.50 |

18.00~ 20.00 | 0.10 | |||||||||||||||||||||||||||

| S30403 | 022Cr19Nil0 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00~ 12.00 |

18.00~ 20.00 |

一 | 一 | 一 | |||||||||||||||||||||||||

| S30409 | 07Cr19Ni10 | 0.04~0.10 | 0.75 | 2.00 | 0.035 | 0.020 |

8.00~ 10.50 |

18.00~ 20.00 | 一 | |||||||||||||||||||||||||||

| $31008 | 06Cr25Ni20 | 0.04~ 0.08 | 1.50 | 2.00 | 0.035 | 0.020 | 19.00~ 22.00 | 24.00~ 26.00 | ||||||||||||||||||||||||||||

| S31608 | 06Cr17Ni12Mo2 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00~ 14.00 | 16.00~ 18.00 | 2.00~ 3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31603 | 022Cr17Ni12Mo2 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00~ 14.00 | 16.00~ 18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31668 | 06Cr17Ni12Mo2Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00~ 14.00 | 16.00~ 18.00 | 2.00~ 3.00 | 一 | 一 | Ti≥5C | ||||||||||||||||||||||||

| S39042 | 015Cr21M26Mo5Cu2 | 0.020 | 1.00 | 2.00 | 0.030 | 0.010 | 24,00~ 26.00 | 19.00~ 21.00 | 4.00~5.00 | 0.10 | 1.20~2.00 | 一 | ||||||||||||||||||||||||

| S31708 | 06Cr19Ni13Mo3 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00~ 15.00 | 18.00~ 20.00 | 3.00~4.00 | 0.10 | 一 | 一 | ||||||||||||||||||||||||

| S31703 | 022Cr19Ni13Mo3 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00~ 15.00 | 18.00~ 20.00 | 3.00~ 4.00 | 一 | ||||||||||||||||||||||||||

| S32168 | 06Cr18Nil1Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 |

9.00~ 12.00 |

17.0~ 19.00 | Ti≥5C | |||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Unified number code | Brand | Chemical composition (mass fraction)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | Other | ||||||||||||||||||||||||||

| 68 | S21953 | 022Cr19Ni5Mo3S2N | 0.030 | 1.30~ 2.00 | 1.00~ 2.00 | 0.030 | 0.020 | 18.00~19.50 | 4.50~ 5.50 | 2.50~ 3.00 | 一 | 0.05~ 0.12 | 一 | |||||||||||||||||||||||

| 70 | S22253 | 022Cr22Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 21.00~ 23.00 | 4.50~ 6.50 | 2.50~ 3.50 | 0.08~ 0.20 | 一 | ||||||||||||||||||||||||

| 71 | S22053 | 022Cr23Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 22.00~ 23.00 | 4.50~ 6.50 | 3.00~ 3.50 | 一 | 0.14~ 0.20 | 一 | |||||||||||||||||||||||

| The chemical composition of some brands in the table is different from that of GB/T 20878 | ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Unified teaching code | Brand | Chemical composition (mass fraction)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Other | |||||||||||||||||||||||||||

| 78 | S11348 | 96C-13A | 0.08 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50~ 14.50 | 0.60 | — | — | Al:0.10~ 0.30 | ||||||||||||||||||||||||

| 92 | S11972 | 019Cr19Mo2NbTi | 0.025 | 1.00 | 1.00 | 0.035 | 0.020 | 17.50~ 19.50 | 1.00 | 1.75~2.50 | 0.035 |

(Ti+Nb) [0.20+4 (C+N)] ~0.80 |

||||||||||||||||||||||||

| 97 | S11306 | 06Cr13 | 0.06 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50~13.50 | 0.60 | 一 | 一 | |||||||||||||||||||||||||

| The chemical composition of some brands in the table is different from that of GB/T 20878 | ||||||||||||||||||||||||||||||||||||

Standard Thickness

Width of stainless steel plate:

1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm.

Non-plate length: 1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm can be determined according to customer requirements.

Cold rolling section:

Stainless steel plate cold rolled 2B (coil, strip, flat plate) characteristic plate: 3 5mm—6mm 304/2B, 316L/2B.

Thickness: cold rolled 2B (0.1-6.0mm).

Surface: 2B smooth surface, BA.

8K mirror; Wire drawing and sanding; Snow sand; Stainless steel fingerprint-free plate.

Decorative panel: color plate, titanium plate, etching plate, oil polishing hairline plate (HL, NO.4), 3D three-dimensional plate, sandblasting plate, embossed plate.

Hot rolling department: stainless steel plate hot rolling No.1 (coil, flat plate).

Thickness: industrial No.1 (3-159mm).

Surface: 8K mirror surface; Wire drawing, titanium plating, sanding; Snow sand; Stainless steel fingerprint-free plate.